The choice between staining concrete and applying an epoxy coating depends on factors such as desired aesthetics, budget, maintenance preferences, intended use of the space, and of course, costs.

Epoxy coatings are durable with various color choices but require more effort to clean due to a slight texture. If you need longevity, epoxy is better for high-traffic areas, needing less maintenance than stained concrete.

Then again, staining is less expensive and easier to install and maintain as a DIY project.

Key Considerations

- Epoxy coatings offer higher durability and customization options.

- Concrete staining is more cost-effective initially but requires more maintenance.

- Epoxy provides a modern, glossy finish ideal for commercial spaces.

- Stained concrete offers a natural, earthy aesthetic with limited color options.

- Consider environmental impact: epoxy contains VOCs, while stained concrete is more eco-friendly.

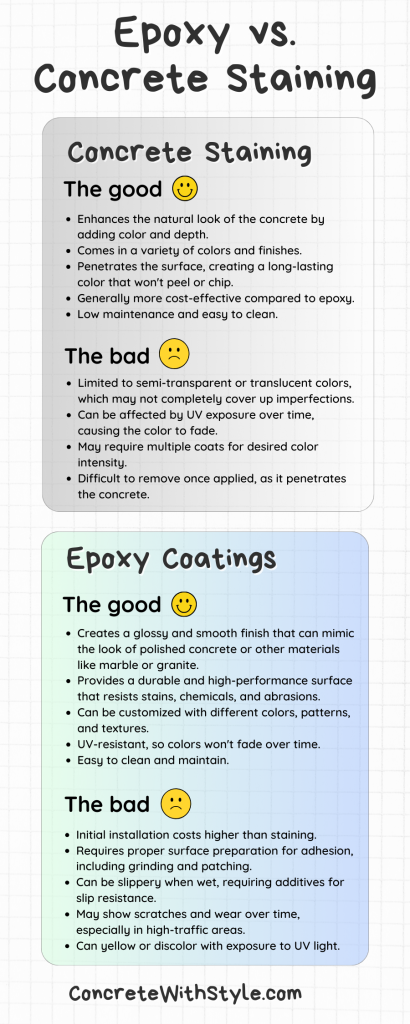

Pros and Cons of Concrete Staining

The good:

- Enhances the natural look of the concrete by adding color and depth.

- Comes in a variety of colors and finishes to suit different design preferences.

- Penetrates the surface, creating a long-lasting color that won’t peel or chip.

- Generally more cost-effective compared to epoxy coatings.

- Low maintenance and easy to clean.

The bad:

- Limited to semi-transparent or translucent colors, which may not completely cover up imperfections in the concrete.

- Can be affected by UV exposure over time, causing the color to fade.

- May require multiple coats for desired color intensity.

- Difficult to remove once applied, as it penetrates the concrete.

Types of Concrete Stains

Concrete stains come in two main types: acid-based stains and water-based stains, each offering different color variations and effects. Acid-based stains produce earthy tones and variegated patterns, whereas water-based stains provide a broader color palette with more uniform hues.

Another option is dye stains. Let’s take a look:

Acid-Based Stains:

- Pros: Creates unique, marbled effects; enhances natural variations in the concrete; long-lasting color.

- Cons: Requires careful application due to its reactive nature; limited color options compared to other types; can be harmful if not handled properly.

Water-Based Stains:

- Pros: Environmentally friendly; easy to clean up; wide range of colors available.

- Cons: May not penetrate as deeply as acid-based stains; colors may appear more muted compared to acid stains; may require multiple coats for desired color intensity.

Dye Stains:

- Pros: Offers vibrant and consistent colors; quick drying time; versatile in creating various design effects.

- Cons: Colors may fade over time with exposure to UV light; may require additional sealant for protection and longevity; can be more expensive than other stain options.

Best places to use concrete stains

When choosing the best locations for applying concrete stains, it’s crucial to consider the advantages and disadvantages of concrete staining to make a well-informed decision.

Concrete stains are most suitable for various commercial spaces, retail locations, schools, showrooms, and outdoor areas. They provide a cost-effective way to enhance the aesthetic appeal of these spaces while offering durability and easy maintenance.

However, it’s important to note that concrete stains may require more maintenance compared to other flooring options, as the surface remains porous. Nonetheless, the polished and shiny finish achieved with concrete stains can transform these areas into visually appealing spaces, making them perfect for businesses looking to make a statement with their flooring choices.

Advantages and Disadvantages of Epoxy Coatings

Epoxy coatings come in various types, each tailored for specific applications. Understanding the different epoxy options available will help you choose the best one for your needs.

The good:

- Creates a glossy and smooth finish that can mimic the look of polished concrete or other materials like marble or granite.

- Provides a durable and high-performance surface that resists stains, chemicals, and abrasions.

- Can be customized with different colors, patterns, and textures.

- UV-resistant, so colors won’t fade over time.

- Easy to clean and maintain.

The bad:

- Initial installation costs can be higher compared to staining.

- Requires proper surface preparation for adhesion, including grinding and patching.

- Can be slippery when wet, requiring additives for slip resistance.

- May show scratches and wear over time, especially in high-traffic areas.

- Can yellow or discolor with exposure to UV light.

Types of Epoxy Coatings

There are several types of epoxy coatings based on their specific properties and applications. Some common types include:

100% Solids Epoxy: Do not contain any solvents and are typically used for high-build applications.

Water-Based Epoxy: Environmentally friendly and have low volatile organic compound (VOC) content. They are suitable for indoor applications.

Metallic Epoxy: Contain metallic pigments that create a unique, three-dimensional look. They are often used in decorative flooring applications.

Anti-Static Epoxy: Formulated to dissipate static electricity and are commonly used in areas where static control is necessary, such as electronics manufacturing facilities.

Self-Leveling Epoxy: Designed to flow and level on their own, resulting in a smooth and seamless finish. They are often used in commercial and industrial settings.

UV-Cured Epoxy: Cure quickly when exposed to ultraviolet light, making them ideal for fast-track projects.

High-Performance Epoxy: Engineered for extreme durability and resistance to chemicals, abrasion, and impact. They are often used in heavy-duty industrial applications.

Best places to use epoxy coatings

For ideal protection and aesthetics, consider using epoxy coatings in high-traffic commercial spaces such as warehouses, retail, lobbies, and factories. Epoxy coatings are highly durable and resistant to wear and tear, making them perfect for areas that experience heavy foot traffic and machinery movement. They are also slip-resistant, ensuring a safe environment for workers.

Professional contractors can apply epoxy coatings seamlessly, providing a smooth and level finish that can withstand the demands of busy environments. Below is a table illustrating the best places to use epoxy coatings:

| Ideal Places for Epoxy Coatings | Benefits | Considerations |

|---|---|---|

| Warehouses/Factories | Durability | Professional application required |

| Retail/Hotels | Slip resistance | Regular maintenance needed |

| Garage/Basement Flooring | Aesthetic appeal | Resistant to chemicals |

When considering epoxy coatings for your project, remember to factor in the application area’s specific requirements to maximize the coating’s advantages.

Durability and Longevity Factors

When considering the durability and longevity factors of concrete stain versus epoxy coating, evaluate their long-term performance and maintenance requirements.

- Durability: Epoxy coatings are more durable than concrete stains, especially when it comes to high-traffic areas like manufacturing spaces. Epoxy withstands foot traffic and resists damage from chemicals and abrasions better than stained concrete.

- Longevity: Epoxy lasts longer with minimal maintenance needs, making it an economical choice over time. Stained concrete, on the other hand, requires regular sealing to maintain its appearance and protect it from stains and wear.

- Versatility: Epoxy offers a wider range of customization options regarding color and finish, allowing for more creative designs compared to concrete stain. This versatility makes epoxy a preferred choice for various spaces where aesthetics play a significant role.

Cleaning and Maintenance Requirements

Maintaining both epoxy floors and stained concrete surfaces involves regular cleaning to guarantee their longevity and appearance remain intact. Epoxy floors and stained concrete are both resistant to stains and only require a wipe if they get soiled. At worst, you’ll need mild soap, water, and a mop to get rid of the toughest soiling.

The only difference is that epoxy is slightly textured than stained concrete and requires a bit more effort to clean. As the sealer on stained concrete fades, you’ll deal with chemical staining. Reapplying a sealant is necessary once or twice a year to prevent permanent discoloration.

Epoxy, when properly installed, forms a durable surface that’s resistant to abrasion, solvents, and thermal shock. While epoxy surfaces may look glossy, they can be made anti-skid by adding anti-slip additives, ensuring safety in wet conditions. Regular maintenance and resealing are essential for stained concrete to maintain its high gloss appearance and guarantee long-term durability.

Safety Considerations for Both Options

Here are some key safety considerations to keep in mind:

- DIY Installation: When opting for stained concrete, especially using acid-based stains, it’s important to exercise caution during the installation process. Acid stains can be harmful to the skin and respiratory system, so protective gear is a necessity. Water-based stains are a safer DIY option due to their reduced toxicity levels.

- Environmental Impact: Acid stains used in concrete staining can have harmful effects on the environment if not handled properly. Dispose of waste responsibly to prevent harm to vegetation and aquatic life. Epoxy coatings have a lower environmental impact and are safer to handle during installation.

- Slip Resistance: Both can be made slip-resistant by adding anti-slip additives. This guarantees safety, especially in areas like hotels and shopping areas where foot traffic is high and the risk of accidents is increased. Prioritizing slip resistance is vital for maintaining a safe environment for guests and visitors.

Aesthetics Comparison: Epoxy Vs. Staining

To compare the aesthetics of epoxy coatings and concrete staining, consider the visual impact each option offers. Epoxy coatings provide a modern and customizable look to your floors, with the ability to add multicolored flecks for a unique touch. The glossy finish of epoxy creates a sleek and attractive appearance, making it ideal for various settings, including basement floors or commercial spaces.

On the other hand, concrete staining offers a more natural and earthy aesthetic, enhancing the existing concrete color while giving it a polished and shiny finish. Staining is preferred when you want to transform the look of your floors while maintaining their original charm. While epoxy allows for intricate patterns and vibrant colors, staining focuses on enhancing the natural beauty of the concrete.

Cost Analysis and Long-Term Investment

When considering the cost analysis and long-term investment, factor in the initial installation expenses and the projected maintenance costs over time.

Initial Installation Expenses: Epoxy coatings typically have higher upfront installation costs due to the materials and labor involved. Concrete staining is generally more cost-effective initially, requiring fewer materials and labor hours. The complexity of the design and surface preparation can also impact the overall installation expenses for both options.

Projected Maintenance Costs: Epoxy coatings are known for their durability and low maintenance requirements, reducing long-term costs. Concrete staining may require more frequent resealing and touch-ups to maintain its appearance, leading to higher maintenance costs over time.

Enivronmental Considerations

Considering the environmental impact of your flooring choice is key to reducing your carbon footprint and ensuring sustainability in your space.

Epoxy generally has a higher environmental impact due to its manufacturing process and the chemicals involved. Epoxy coatings often contain volatile organic compounds (VOCs) that can be harmful to both human health and the environment.

On the other hand, concrete staining is typically more environmentally friendly as it involves natural acids and pigments that are less harmful. In terms of sustainability, concrete stain is often the more eco-friendly option as it allows the concrete to breathe naturally, reducing the need for additional materials.

If environmental considerations are a top priority for your project, concrete staining may be the more sustainable choice for your space.

Frequently Asked Questions

Can Epoxy Coatings Be Applied Over Existing Stained Concrete Floors?

Yes, epoxy coatings can be applied over existing stained concrete floors. Proper preparation, including cleaning and etching, is vital for adhesion. Consult a professional to guarantee compatibility and best results for your project.

Are There Any Specific Environmental Considerations to Keep in Mind When Choosing Between Concrete Staining and Epoxy Coatings?

When choosing between concrete staining and epoxy coatings, consider that epoxy is more environmentally friendly as it emits fewer volatile organic compounds (VOCs). This makes epoxy a safer and greener choice for your project.

How Do the Long-Term Costs of Maintaining Stained Concrete Compare to Epoxy Coatings?

When comparing long-term maintenance costs, epoxy coatings require less effort and expense than stained concrete. Epoxy is durable and resistant, needing minimal care. Stained concrete, on the other hand, demands frequent sealing leading to higher expenses over time.

Are There Any Special Considerations for Cleaning and Maintaining Epoxy Floors in High-Traffic Areas?

In high-traffic areas, routinely clean epoxy floors with a mild soap and water solution using a mop. For tough stains, gentle scrubbing is effective. Incorporate anti-slip additives for safety. Minimal upkeep guarantees longevity.

Can Epoxy Coatings Be Customized to Match Specific Color Schemes or Design Preferences?

Yes, epoxy coatings can be fully customized to match your specific color schemes and design preferences. You have the freedom to choose from a wide range of colors and even add multicolored flecks for a unique and personalized finish.